Blog

The difference between SGL and HPL

Solid Grade Laminate and High Pressure Laminate are the two most common and popular materials in washroom specifications, used for Cubicles, IPS Duct Panelling Vanity Tops and Vanity Units.

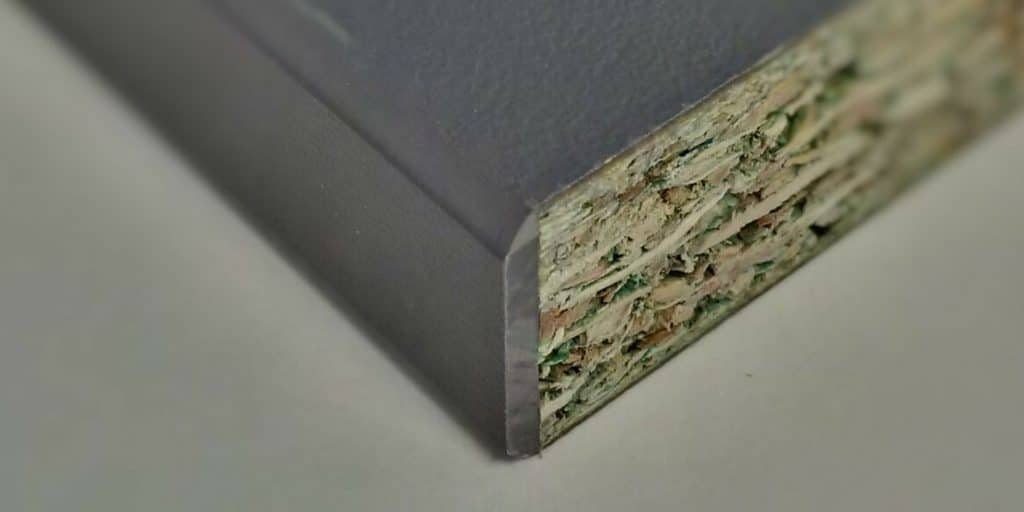

The difference between the two materials lies within the core – although the materials look similar from the outside and are often available with the same colour, pattern or woodgrain finish, the material under the finish is very different.

High Pressure Laminate

HPL is considered to be one of the most durable, decorative surface materials available and boasts enhanced performance properties. HPL is produced by sandwiching layers of paper and phenolic resins and fusing them together under intense heat and pressure. The thermosetting process transforms the resins into plastic and converts the paper sheets into a single, rigid laminated sheet with one decorative side. The resulting laminate is strong, durable and water resistant.

A versatile product, HPL offers superior resistance against impact, abrasion and general surface wear. As its surface is impervious to water, it’s ideal for use in a range of applications and particularly so, in washroom environments. A popular choice, HPL will withstand medium to intense use, making it the perfect specification for areas such as office and commercial washrooms.

However, HPL with its chipboard core isn’t suitable for areas which are constantly wet or have a high amount of traffic, which is why its steered away from in high volume, heavy traffic areas such as School Washrooms and wet washrooms such as Leisure Centres and Shower Facilities.

Solid Grade Laminate

SGL offers similar surface advantages to HPL but is a denser, self-supporting panel that offers enhanced performance for high traffic environments. Constructed from multiple layers of high-quality paper, impregnated with thermosetting phenolic resins, the layers undergo the same heating and high-pressure compression as HPL. In the case of SGL, the layers form a single, high strength, tough and totally waterproof panel. The resulting panel has a characteristic black core with two decorative sides. It’s a high-performance material that offers distinct advantages and is ideally suited to applications where technical performance is paramount.

SGL is designed for use in hard-working washroom applications. Particularly suited to high humidity environments, SGL is totally impervious to water making it key for shower cubicles and wet changing rooms.

SGL is also a must in any areas with high usage and where vandalism may be an issue making it a popular choice in school toilets, SGL offers extreme impact resistance.