HPL Vanity Unit systems are supplied with complementary access panel and sub- frame system for a complete Commercial Vanity Unit solution, alternatively the Postformed Top can be supplied alone if required.

The Vanity Unit system comes with a post- formed downstand and upstand as standard.

Gallery

High Pressure Laminate (HPL) Vanity Unit specification

Tops: Postformed HPL Laminate

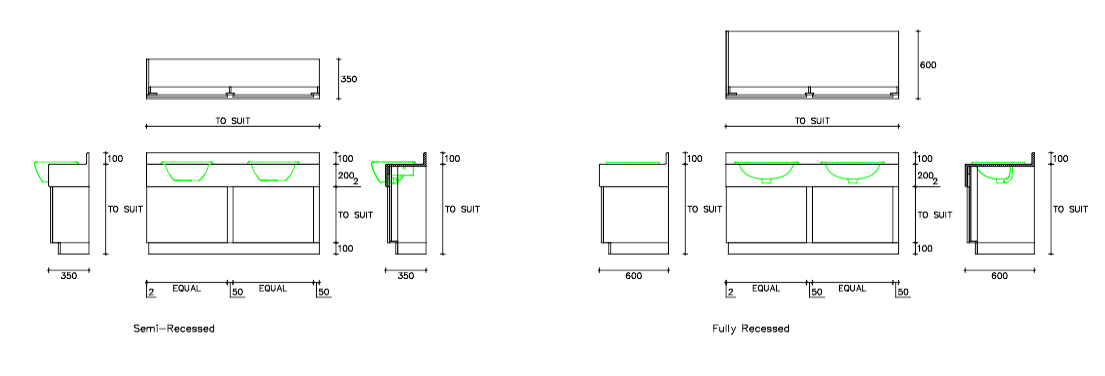

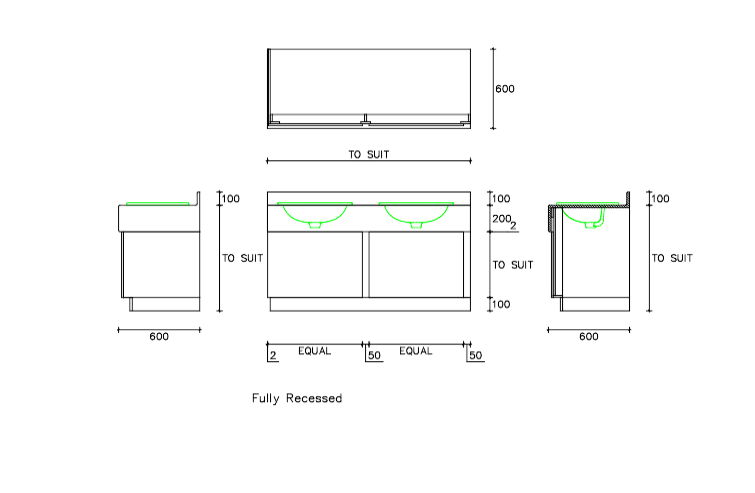

Fully Recessed HPL Top Construction:

Style: 18mm thick, 200mm post-formed front apron and 100mm high coved

rear upstand

Depth: 600mm for inset basins

Core/Face: High pressure laminate on 18mm MR MDF

Colours: ref to Cube colour selector

Cut-Outs: Bowl cut-outs are not included unless mentioned seperately

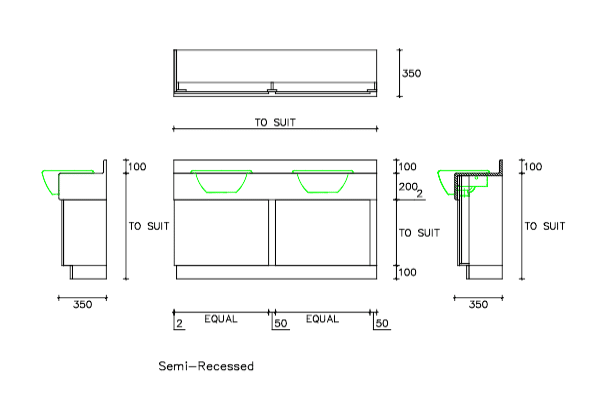

Semi Recessed HPL Top Construction:

Style: 18mm thick, 200mm post-formed front apron and 100mm high coved

rear upstand

Depth: 300mm/350mm for semi-recessed basins

Core/Face: High pressure laminate on 18mm MR MDF

Colours: ref to Cube colour selector

Cut-Outs: Bowl cut-outs are not included unless mentioned seperately

Unit Construction - Panels

SGL Panel Option:

SGL Core/Face: 13mm solid grade laminate panels

SGL edge: profile radiused and polished

Colour: ref to Cube colour selector

HPL Panel Option:

HPL Core/Face: 18mm high pressure laminate panels – high density particle-

board faced both sides with high pressure laminate.

HPL edge: matching 2mm thick impact resistant ABS lipping

Colour: ref to Cube colour selector

Unit Construction - Frames

Softwood subframe fitted with lift off access panels and 100mm integral laminated plinth.

Options

Unit construction options:

Height: low height options available

18mm MFC carcass unit with shelves and hinged door